Flow/Consumption

S 401 FLOW/CONSUMPTION SENSOR (INSERTION TYPE)

- Insertion type sensor for flexible installations under pressure

- Two calibration curves can be saved on to the sensors internal memory

- Due to the two calibration curves the sensor can be used with highest precision in two different gases

- Velocity, Flowrate, Consumption and Temperature are displayed

- IP65 protection class offers a rugged protection in rough industrial environment

- Isolated analog and pulse outputs or MODBUS/RTU interface

- Thermal mass flow measurement, pressure and temperature independent

- Very fast response time, high precision and wide measuring range

- Pipe diameters from 1” … 12” – others on Request

The S 401 flow and consumption sensor covers a wide measuring range. With the high resolution and sampling rate a very fast and precise measurement is achieved. The sensors is able to save two calibration curves, due to this the sensor can be used in two different gases without any loss of accuracy. The optional color display is designed to show all measured values, at the same time it can be used to manage the sensor settings like pipe diameter, gas type or analog output scaling. The sensor offers two different signal output options. It can have a isolated analog and pulse output to read out the flow and the total consumption. Alternatively a MODBUS/RTU interface can be used to access all measured values via the digital interface.

Various settings such as gas type, flow unit, reference standards, can be set ex factory, through our service kit or through the optional display. The service kit consists of a PC software and a interface box which connects the flow meter to the USB port of the PC.

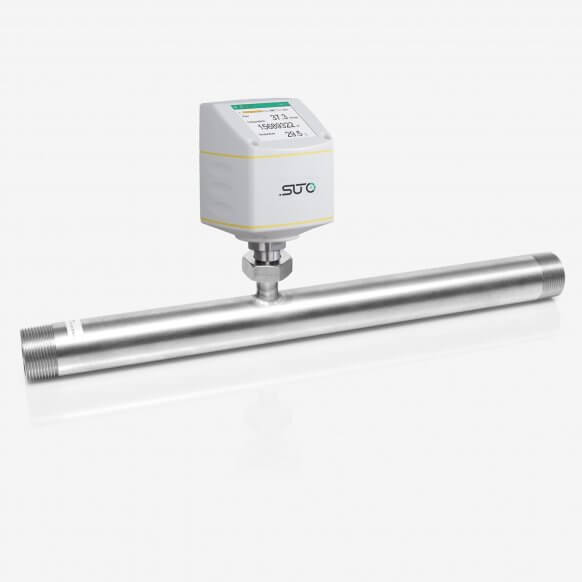

S 421 FLOW AND CONSUMPTION SENSOR FOR COMPRESSED AIR AND GASES (INLINE-SENSOR)

- Easy and affordable sensor solution to measure the compressed air flow and consumption

- Sensor is calibrated in the measuring section, this allows a very high precision

- Two calibration curves can be saved on to the sensors internal memory

- Due to the two calibration curves the sensor can be used with highest precision in two different gases

- Velocity, Flowrate, Consumption and Temperature are displayed

- IP65 protection class offers a rugged protection in rough industrial environment

- Isolated analog and pulse outputs or MODBUS/RTU interface

- Thermal mass ow measurement, pressure and temperature independent

- Very fast response time, high precision and wide measuring range

- Pipes sizes available: DN15, DN20, DN32, DN40, DN50, DN65,DN80

- Integrates seamlessly in your compressed air system

- Fits your needs: various process connections available(R-thread, EN 1092-1 ange or ANSI ange)

- Exchangeable sensor unit (easy sensor swap)

- Optional ow conditioner, no need for a straight inlet anymore

S 450 FLOW/CONSUMPTION SENSOR (HD)

- Heavy duty version

- Direct measurement of mass flow and standard flow without the need of pressure compensation

- Wide range of tube sizes are supported (insertion type for big pipe diameters / inline types for small ones)

- No moving parts, non clogging

- All parts which come into contact with the measurement medium are made of stainless steel 316L

- Robust metal enclosure suitable for out-door applications in harsh environment

- Wireless BlueTooth interface for sensor settings on site

- Display shows flow rates, consumption, medium temperature and diagnostic results

- 2 analogue outputs (4 … 20 mA) and 1 pulse output

Available options:

– Fieldbus interface: HART, Modbus, M-BUS

– Hazardous approval ATEX: II 2 G Ex d IIC T4, IECEx approval, GB Ex approval

– 2-directional measurement

– Flow conditioning

The Nexuz flow sensor S 450 is based on the thermal mass flow principle. It measures volumetric standard flow over a wide measuring range. The result is pressure and temperature independent.

The S 450 is designed specifically for harsh environments. The enclosure with IP67 allows all-weather applications, all parts which come into contact with the measurement medium are made of stainless steel 316L. This allows applications in pharmaceutical and food industry, but also the measurement of corrosive and contaminated gas. Installations in explosive environment can be done through the optional ATEX approval. Various gases can be measured such as air, oxygen, argon, carbondioxyde, natural gas, hydrogen, methane, etc. Basically any gas mixture can be measured as long the mixing ratio and its components are known and constant.

S 452 FLOW/CONSUMPTION SENSOR (HD, INLINE)

- Heavy duty version as inline type

- Direct measurement of mass flow and standard flow without the need of pressure compensation

- Wide range of tube sizes are supported with insertion type for big pipe diameters and in line types for small pipe diameters

- No moving parts, non clogging

- All parts which come into contact with the measurement medium are made of stainless steel 316L

- Robust metal enclosure suitable for out-door applications in harsh environment

- Wireless BlueTooth interface for sensor settings on site

- Display showing flow rates, consumption, medium temperature and diagnostic results

- 2 analogue outputs (4 … 20 mA) and 1 pulse output

Available options:

– Fieldbus interface: HART, MODBUS

– Hazardous approval ATEX: II 2 G Ex d IIC T4, IECEx approval, GB Ex approval

– 2-directional measurement

– Flow conditioning

The Nexuz flow sensor S 452 is based on the thermal mass flow principle. It measure volumetric standard flow over a wide measuring range. The result is pressure and temperature independent.

S 452 is designed specifically for harsh environments. The NEMA 4X enclosure with IP67 allows all-weather applications, All parts which come into contact with the measurement medium are made of stainless steel 316L. This allows applications in pharmaceutical and food industry, but also the measurement of corrosive and contaminated gas. Installations in explosive environment can be done through the optional ATEX approval. Various gases can be measured such as air, oxygen, argon, carbondioxyde, natural gas, hydrogen, methane, etc. Basically any gas mixture can be measured as long the mixing ratio and its components are known and constant.

S 430 FLOW/CONSUMPTION SENSOR (PITOT TUBE FLOW)

- Flow and consumption measurement in wet air or high mass flow / velocity applications

- Measurement at compressor outlet possible

- Tube diameters of 1” … 10”. Other diameters on request

- Insertion type, easy installation under pressure through ball valve possible

- High temperature applications up to 200 °C

- No mechanical wear parts

- All parts which are in contact with flow medium are made of stainless steel

- Compressor-FAD-Measurement

The S 430 is based on the pitot tube principle to measure flow. Properly installed (refer to instruction manual for details) the sensor can measure in wet and dirty gases as occurring, for example, at the discharge of a compressor.

The sensor features long term stability , wide turn-down ratio and good temperature stability. It can be used in compressed air and non-corrosive gases. Through a 1/2” G-type ball valve the sensor can be inserted into the pipe under pressure. Various output signals allow the sensor to be connected to Nexuz displays and/or third party displays and PLCs.

S 460 ULTRASONIC FLOW METER

- Easy to install for permanent and temporary installations

- High accuracy

- Physical units can be selected

- Excellent price performance

- Suitable for DN32 – DN6000

- Plug & play for Nexuz display & data logger

The S 460 ultrasonic flow meter uses the proven clamp-on transit-time correlation technique. The ultrasonic transducers are simply clamped onto the outside of the pipe and never come in contact with the fluid. The transducers are connected to a controller which is available as hat rail, or portable version. The stationary models can be connected to the S 330/331 series of displays and data loggers where the portable model is connectable to the S 551.

Theme redesign by ONEZZZ for PT.Calistacitra Lestari.